In the rapidly advancing world of technology, the demand for high-performance lithium batteries is skyrocketing. From electric vehicles to renewable energy storage, lithium batteries have become the backbone of modern energy solutions. Ensuring the quality and longevity of these batteries, however, requires precise manufacturing conditions. This is where lithium battery dehumidification dry rooms suppliers play a critical role. A custom lithium battery dry rooms factory provides tailored solutions to meet the stringent requirements of high-tech battery production, offering environments designed to control moisture, dust, and temperature with utmost precision.

The Importance of Dry Rooms in Lithium Battery Manufacturing

Lithium batteries are highly sensitive to moisture during manufacturing. Even a small amount of water vapor can cause defects such as lithium dendrite formation, short circuits, or reduced battery life. To combat these risks, dry rooms are engineered to maintain ultra-low humidity levels, typically below 1% relative humidity. By controlling the environment so strictly, manufacturers can ensure consistent quality, higher yields, and safer battery performance.

Custom dry rooms are particularly important for companies producing high-capacity cells or exploring next-generation battery technologies. Unlike generic cleanrooms, custom lithium battery dry rooms are specifically designed to cater to the delicate nature of lithium-based energy storage solutions. They incorporate precise air filtration, humidity control, and temperature management systems to create a controlled manufacturing environment.

How Lithium Battery Dehumidification Dry Rooms Suppliers Enhance Production

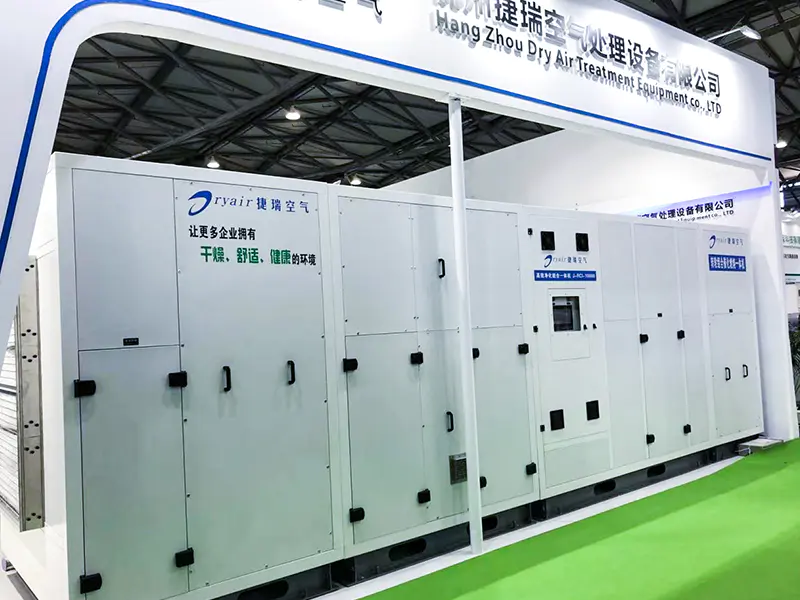

Lithium battery dehumidification dry rooms suppliers are specialized experts who provide turnkey solutions for battery manufacturers. Their services typically include design consultation, installation, and ongoing maintenance. By collaborating with these suppliers, factories can benefit from solutions tailored to their production volume, space constraints, and technological requirements.

Advanced dry rooms feature high-capacity dehumidification units that remove moisture continuously, ensuring that the air remains extremely dry. Sophisticated monitoring systems allow operators to track environmental conditions in real-time, detecting even minor deviations that could compromise battery quality. Many suppliers also offer modular designs that allow easy expansion as production scales, making these solutions highly flexible for growing businesses.

Key Features of Custom Lithium Battery Dry Rooms

Custom lithium battery dry rooms come with a variety of specialized features:

- Ultra-Low Humidity Control: Maintaining less than 1% relative humidity prevents oxidation and moisture-related defects in lithium cells.

- Temperature Stability: Consistent temperatures reduce stress on battery materials during production and assembly.

- Advanced Air Filtration: HEPA and ULPA filters remove dust and airborne particles, creating a clean manufacturing environment.

- Modular Design Options: Modular systems allow manufacturers to expand or reconfigure dry rooms without major reconstruction.

- Real-Time Monitoring: Digital control systems monitor humidity, temperature, and air pressure, ensuring compliance with stringent battery manufacturing standards.

- Energy Efficiency: Modern dehumidification systems are optimized to consume less energy, lowering operational costs while maintaining high performance.

By integrating these features, manufacturers can create conditions that maximize battery performance, safety, and longevity, all of which are essential for staying competitive in the high-tech energy market.

Choosing the Right Dry Room Supplier

Selecting a reliable lithium battery dehumidification dry rooms suppliers is critical for achieving optimal results. Factors to consider include the supplier’s experience in battery manufacturing, customization capabilities, and support services. A supplier with a strong track record in lithium battery production can offer insights into design optimization, maintenance schedules, and energy-efficient solutions.

Additionally, collaboration with the supplier during the planning phase ensures that the dry room meets specific production needs, including layout, throughput, and integration with other manufacturing equipment. High-quality suppliers also provide training for factory personnel, ensuring safe and efficient operation of the dry room.

Benefits of Custom Dry Rooms for Lithium Battery Production

Investing in a custom lithium battery dry rooms factory offers several key advantages:

- Enhanced Product Quality: Strict control over environmental factors reduces the likelihood of defects, improving battery reliability.

- Increased Production Yield: Fewer defective batteries mean higher output and reduced waste.

- Improved Safety: Proper humidity and temperature control minimize the risk of chemical reactions and battery failures.

- Scalability: Custom dry rooms can be adapted to meet growing production demands without significant downtime.

- Regulatory Compliance: Many battery applications require adherence to strict manufacturing standards, which can be achieved more easily in a controlled dry room environment.

These benefits make custom dry rooms not just a convenience but a strategic necessity for lithium battery manufacturers aiming for excellence.

Innovations in Lithium Battery Dry Room Technology

The field of lithium battery dry rooms is continuously evolving, with suppliers incorporating new technologies to improve efficiency and reliability. Innovations include smart dehumidification systems that automatically adjust airflow and moisture removal based on real-time sensor data, as well as energy recovery solutions that reduce operating costs.

Some suppliers are also developing modular cleanroom systems that integrate seamlessly with battery production lines, allowing for faster installation and flexible reconfiguration. Advanced control software now allows remote monitoring and predictive maintenance, reducing downtime and ensuring consistent production quality.

Conclusion

As the demand for lithium batteries continues to rise, maintaining the highest standards in manufacturing has become essential. A custom lithium battery dry rooms factory provides the tailored solutions necessary to achieve these standards, ensuring ultra-low humidity, temperature stability, and clean air conditions. Working with experienced lithium battery dehumidification dry rooms suppliers enables manufacturers to optimize production, enhance battery performance, and ensure safety.

Investing in a custom dry room is more than just an infrastructure decision—it is a commitment to quality, innovation, and long-term success in the high-tech energy sector. By choosing the right supplier and embracing cutting-edge technology, battery manufacturers can meet the challenges of modern energy storage while delivering products that set the standard for reliability and performance.